PUMP TECHNOLOGY

How it works

The Double Point Pump combines the strong features of a centrifugal pump and a positive displacement pump. The pump has an almost constant flow and pressure, no valves, and a fixed pump volume per revolution.

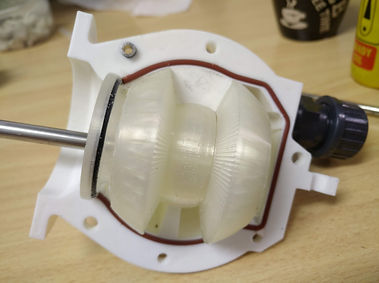

The design consists of a bellows and two chambers. The pumping function is activated by increasing the inflow space and decreasing the outflow space in the pump. The change in the volumes of the pump chambers is the result of a twist in the drive shaft outside the pump. This twist causes a tilting of the displacer because the middle part of the shaft is at an angle relative to the ends of this shaft. The configuration of the shaft can vary depending on the application.

Double Point Pump

BENEFITS

Not only does the Double Point Pump maintain an almost constant pressure, is it self-priming and does it not easily seize contaminate or leak, but the newly engineered design also offers a number of other significant benefits:

-

Compact and easily scalable

-

Small pump size, large output

-

Suitable for various applications, from domestic to industrial

-

Bidirectional pumping capabilities

-

Quiet operation

-

Pumps suspended solids (in dirty water for example)

-

Accurate dosing (fixed volume per cycle)

-

Easy to maintain (no openings or valves)

-

Hygienic (can be supplied in full flow-through design)

-

Preserves the liquids’ characteristics

-

Liquid is moved at a constant speed

-

Can be made frost-resistant

THE INVENTOR

Working in his own company GJD Technics, engineer Gert-Jan Droogers develops technical products. One of these is his patented Double Point Pump. In his search for a simple pump with a unique combination of properties, he invented and engineered the innovative pumping technology behind this remarkable pump.